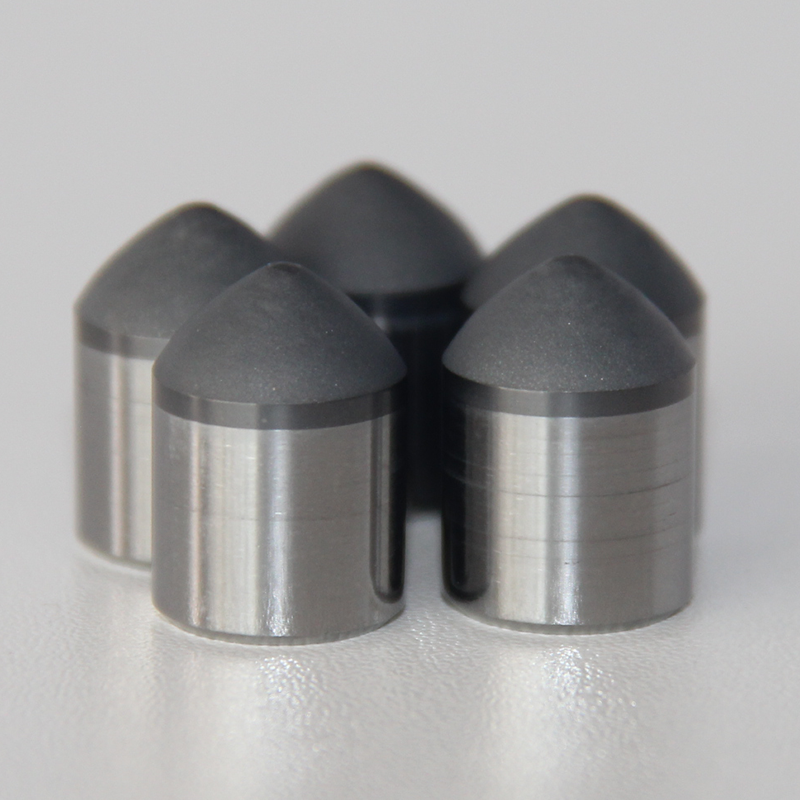

C1113 conical Diamond composite teeth

| Product Model |

D Diameter | H Height | SR Radius of Dome | H Exposed Height |

| C0606 | 6.421 | 6.350 | 2 | 2.4 |

| C0609 | 6.400 | 9.300 | 1.5 | 3.3 |

| C1114 | 11.176 | 13.716 | 2.0 | 5.5 |

| C1210 | 12.000 | 10.000 | 2.0 | 6.0 |

| C1214 | 12.000 | 14.500 | 2 | 6 |

| C1217 | 12.000 | 17.000 | 2.0 | 6.0 |

| C1218 | 12.000 | 18.000 | 2.0 | 6.0 |

| C1310 | 13.700 | 9.855 | 2.3 | 6.4 |

| C1313 | 13.440 | 13.200 | 2 | 6.5 |

| C1315 | 13.440 | 15.000 | 2.0 | 6.5 |

| C1316 | 13.440 | 16.500 | 2 | 6.5 |

| C1317 | 13.440 | 17.050 | 2 | 6.5 |

| C1318 | 13.440 | 18.000 | 2.0 | 6.5 |

| C1319 | 13.440 | 19.050 | 2.0 | 6.5 |

| C1420 | 14.300 | 20.000 | 2 | 6.5 |

| C1421 | 14.870 | 21.000 | 2.0 | 6.2 |

| C1621 | 15.880 | 21.000 | 2.0 | 7.9 |

| C1925 | 19.050 | 25.400 | 2.0 | 9.8 |

| C2525 | 25.400 | 25.400 | 2.0 | 10.9 |

| C3028 | 29.900 | 28.000 | 3 | 14.6 |

| C3129 | 30.500 | 28.500 | 3.0 | 14.6 |

Why choose conical diamond composite teeth?

- Superior Wear Resistance: Utilizes a high-temperature, high-pressure sintered diamond layer, achieving a hardness of HV10000+, extending service life by 25% compared to ordinary composite teeth, reducing drill bit replacement frequency and lowering downtime costs.

- High Impact Resistance: Remains crack-free after 1200 50J impact tests. The base material is made of high-quality cemented carbide, and the conical structure disperses impact force, adapting to complex geological vibration environments and reducing the risk of equipment damage by 40%.

- Highly Efficient Rock Breaking Power: The conical design reduces the rock contact area, increasing unit pressure by 30%, easily conquering formations with a hardness of 8-12, increasing drilling speed by 20-30%, and shortening the construction period.

Application

- Oil and Gas Drilling: Suitable for wells 3000-5000 meters deep, tackling complex formations such as sandstone and shale;

- Mineral Resource Extraction: Used for coal and metal mine drilling, handling high-wear and high-impact conditions;

- Geological Exploration Drilling: Suitable for complex field formations, ensuring the accuracy of exploration data;

- Water Conservancy Project Drilling: Used for reservoir and bridge foundation drilling, improving construction efficiency.

Factory

C1113 Tapered Diamond Composite Tooth Customization Service | Precisely Fits Your Dedicated Drilling Conditions

- Customizable Dimensions (Core Adaptation)

- Basic Dimensions: Diameter (3mm-35mm), Height (5mm-30mm), Dome Radius (0.5mm-5mm), Exposure Height (2mm-15mm)

- Special Structures: Customizable conical, spherical, and conical-spherical shapes to match non-standard drill bit designs.

2.ustomized Performance and Processes (Enhanced Adaptation)

- Wear Resistance Upgrade: For high-wear formations, thickened diamond layer (0.5mm-2mm), increasing hardness to HV10500+

- Impact Resistance Enhancement: For high-vibration conditions, optimized substrate formulation (hard alloy + special binder), increasing impact strength to 60J;

- Special Coatings: Optional diamond coating or TiN coating, enhancing high-temperature resistance (≤800℃) and corrosion resistance, adapting to extreme drilling environments.

Material

Quality control

Certification

Write your message here and send it to us